When working with a Siemens automaton, you must parameterize the communications :

the address of the automaton on the MPI, Profibus or Industrial Ethernet network ;

the addressing of the virtual Inputs/Outputs to the automaton.

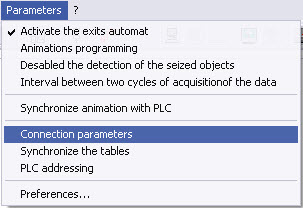

The menu ‘Parameters’ is used to configure the connection.

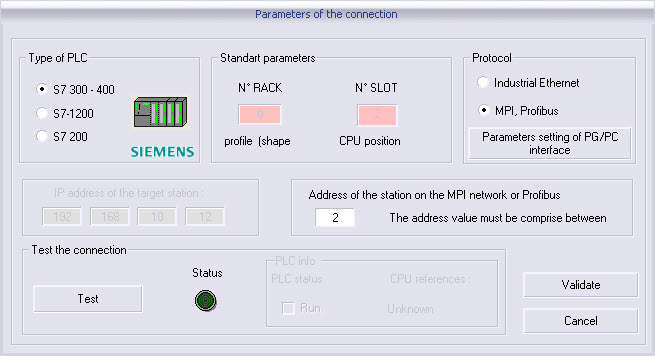

Connection parameters define the PLC adressing and the choice of the network :

1. Select the PLC type.

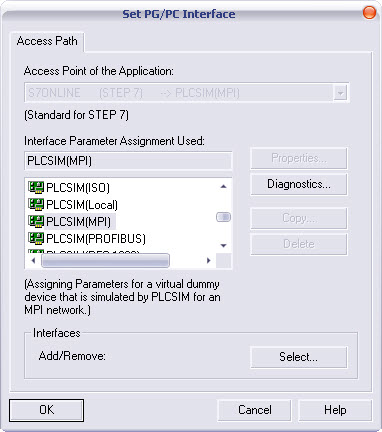

2. Define the protocol and the parameters the PG/PC interface.

The "Access Point of the Application" must be defined on "S7ONLINE".

The parameters used must be defined in a identical way in the Step 7 and Microwin softwares.

3. Define the PLC address.

4 .Test the connection.

5. Validate.

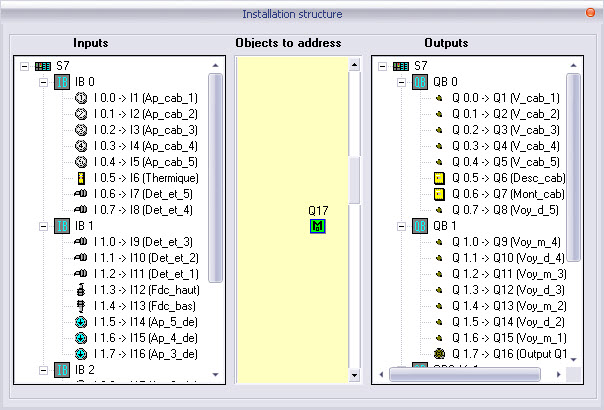

The addressing of the virtual I/O by PLC addressing perform in two times

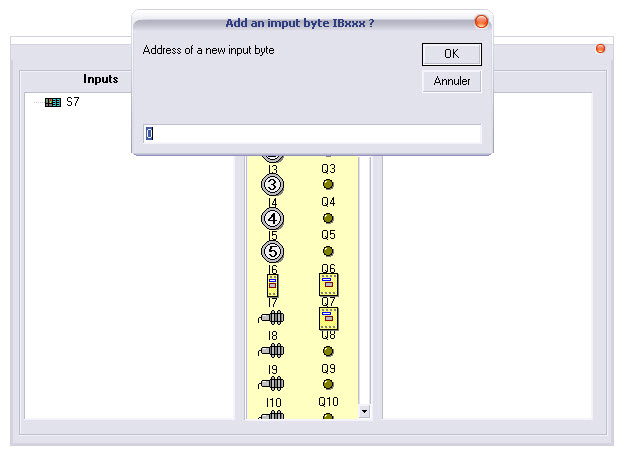

1. Add input and output bytes by clicking with the right button on the S7 root.

2. Placement of the virtual elements on their desired locations by using "Drag and Drop" :

‘On-off’ elements on the developed bytes ;

the data of thumbwheel counters and the data of BCD displays on the bytes ;

the words require two consecutive bytes in accordance with the addressing convention.

Addressing of thermal overload relays to I1.1

The deletion of the addressing of a bit or a byte is made with the right button of the mouse.

Editing one byte is done with the left button (Modification of addressing).

Warning

When modifying the address of the automaton on the MPI network, it is imperatively required to restart the PC.

Then define in ProccesSim the new address of the automaton.